On arrival at Richmond Hill waste vehicles use an automatic weighbridge set back from the site entrance, so that lorries do not have to queue on the public highway. Waste types and amounts, as well as customer details, are recorded and drivers are directed to the appropriate despatch bay.

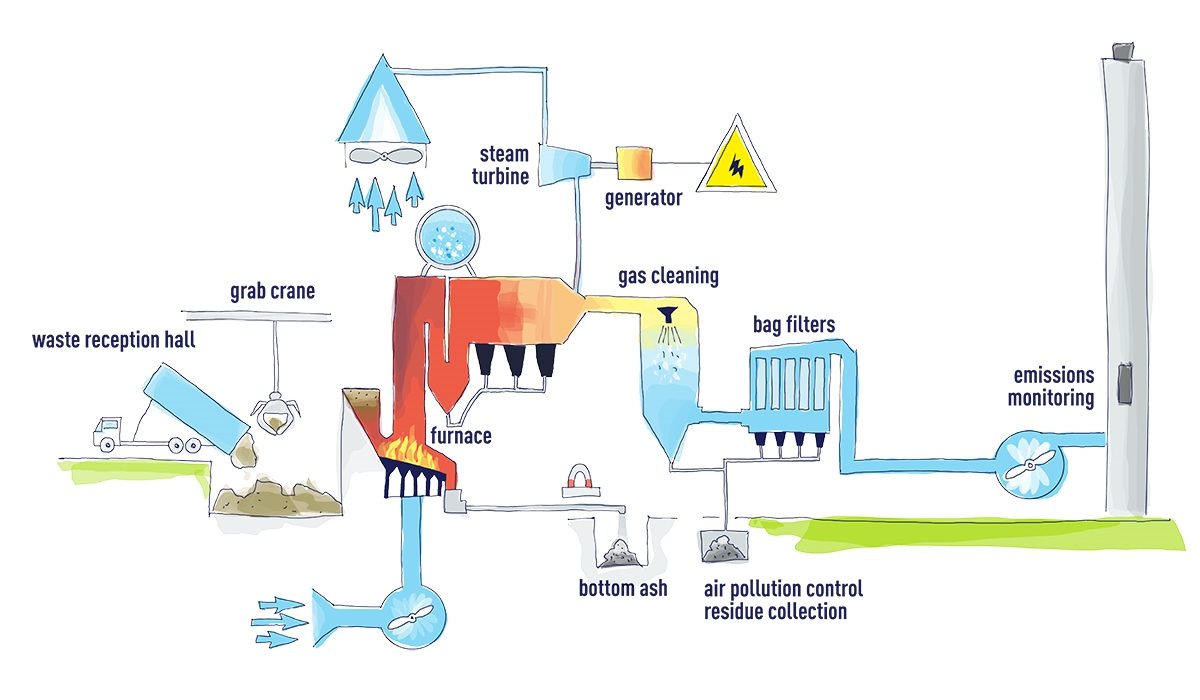

Reception hall

A large reception hall allows refuse collection vehicles to manoeuvre and tip waste safely. Air needed for the combustion process is drawn into the furnace from here, so that odour and dust do not escape from the building.

Bunker

Waste vehicles reverse to a wheel-stop and tip their loads into a large concrete bunker. This is big enough to hold 16 days’ waste, so that tipping can continue when the facility is shut down for maintenance. A shredder, for bulky items such as mattresses, also discharges material directly into the bunker.

Control room

The facility’s control room centralises the operation of all equipment, including the grab crane used to mix and load waste into a hopper that feeds the furnace. All on-site functions are monitored both automatically and manually. Control systems verify in real time that equipment is functioning properly, continuously monitor the levels of combustion gas and maximise the efficiency of the entire energy-from-waste process.

Grate and boiler

Combustion air is blown up into the bottom of the water-cooled grate through five computer-controlled zones. The thermal energy released from the burning is used to convert water into super-heated steam. At high pressure, this steam drives a turbine-alternator to generate electricity.

Electricity generation

Electricity is generated at 11kV. At full capacity, around 1.5 megawatts is used to power the facility, leaving up to 5.5 megawatts for export to the Manx Electricity Authority, which distributes it around the island. The facility’s switchgear is designed to protect the island’s supplies from interruption.

Bottom ash

Ash left on the grate after incineration is carried by conveyor, after quenching, to a storage bunker. A magnet above the conveyor extracts ferrous material for recycling. The remaining bottom ash is sampled for contaminants before being removed for disposal to landfill.

Air‑cooled condensers

After exiting the turbine, the air stream is cooled and condensed back into water through air condensers. This recovered water is treated and reused in the boilers to produce more steam.

Emission control

The gases from the furnace are subject to a rigorous cleaning process involving selective non-catalytic reduction, spray absorbers and active carbon injection. This removes oxides of nitrogen, acidic gases, dioxins and heavy metals from the gas stream.

Air pollution control residue

The cleaned gas is passed through fine-fabric bag filters to remove solid particles before it is emitted through the stack. The resultant air pollution control residue, or fly-ash, contains particles from the incineration process, lime used in the spray absorbers, salts and carbon dust. It is analysed for contaminants and stored in a sealed silo or UN approved bags until it is collected for disposal in specialist authorised facilities.

Emissions monitoring

As they pass through the stack, the residual flue gases from the process are continuously monitored before release. This data is relayed automatically to the control room and to a secure recorder.